Preheat Frustrations

- Details

- Written by Kevin Horton

- Hits: 2817

Monday afternoon it was quiet at work, and I needed to clear the recent snow from in front of the hangar, so I took some comp time. Much to my surprise and delight, I found that Ron, the hangar owner, had just finished clearing the snow when I arrived. He had the day off, and must have felt like getting out of the house.

I hooked up the remote preheat control, and did some tests. I put it right next to a window, and the cell phone has an excellent signal. The control worked perfectly, so I left it running and came home.

Sunday morning, it was clear and cold. I made the two phone calls to trigger the preheat timer at 6:45, and drove out to the hangar just before lunch time, hoping to find that the engine was nicely warmed up. Instead, I found it stone cold, with the preheater not running. Drat. I could find no obvious reason why it had not come on. I did several more tests, and it worked every time. I’m not sure if I have an intermittent hardware problem, a software bug, or whether there was a momentary power outage. The current software always starts up with the preheat OFF. I plan to update it to periodically write the timer status to the EEPROM that stores the program, and to check the status when it starts up. If it finds that the timer was running on shutdown, it will turn it back ON at startup. I only recently found a forum thread that describes how to write to the EEPROM without erasing the program that the Parallax Propeller micro-controller loads from the EEPROM on startup, or I would have written the software to do this from the start of this project.

I know that Ron had to reset the breaker for the hangar door - perhaps the power to the remote control got interrupted somehow. I’ll need to do a bunch of testing before I can trust the code to write the status to the EEPROM, and I’ll need another Prop to do the testing on. My only Prop is at the hangar now, but I’ve ordered some more that should arrive in a couple of weeks. I’ll update the software the next time I’m at the hangar to have the preheat default to ON following a power failure. It will then go OFF after six hours. After plugging the system in, I’ll use the manual control to put the preheat OFF.

I am still agonizing over whether I should just leave the preheater plugged in continuously, or whether I should continue to only have it run prior to going flying. I have heard stories that claimed that a preheat system that runs continuously may lead to internal engine corrosion. The oil in the engine collects moisture when the engine is running, as the combustion gasses that blow by the piston rings have water in them - a byproduct of the combustion process. The air in the crankcase is also quite moist, for the same reason. It is quite likely that some of this moisture will condense inside the crankcase if the engine cools down to a cold enough temperature. If the whole engine was kept warm enough, there should be no internal condensation. This theory is supported by a study done by Aviation Consumer. But, this study was only on one engine, and it only lasted seven days. There is another theory, that if the engine oil is warmed by a preheat system, that this could cause some of the moisture may be pushed into the air in the crankcase, and this may increase the amount of condensation that forms if the top of the crankcase remains cold. The jury is still out in my opinion, and I’m not yet comfortable taking the risk.

I got a short flight off on Sunday, but it was delayed as I had to wait while the preheater did its magic. The runway was in much better shape - only 20% ice covered vice 70% the last time I flew. I did a few aerobatics, and some touch and goes. It was a nice flight.

Engine Preheat Remote Control Prototype

- Details

- Written by Kevin Horton

- Hits: 4203

I’ve spent quite a bit of time over the last few weeks learning the ins and outs of the Parallax Propeller micro-controller (Prop). Once I learned the basics, I started working on a remote control system for the RV-8 engine preheater. The concept of operations is to use a cell phone to trigger the preheater. The cell phone display illuminates when it receives a call, then goes dark a few seconds later. The illumination or dark state of the display can be detected by a CdS photocell connected to the Propeller micro-controller. Two calls received in an 80 second period will cause the Propeller to close a solid state relay (SSR) which controls the preheater, and leave it ON for six hours. If two more calls are detected it will reset the timer to 6 hours, to cover the case where my arrival at the airport is delayed. Three calls in 120 seconds will set the preheat to OFF if it was ON.

The Prop is really overkill for this mission, but I wanted to get some experience with it as I have some thoughts about using it in the future for a pitch axis autopilot. The 8 CPUs in the Prop are ideal for my autopilot project, as I will be able to give some important tasks their own CPU to ensure they happen on schedule, no matter what other busy tasks are running.

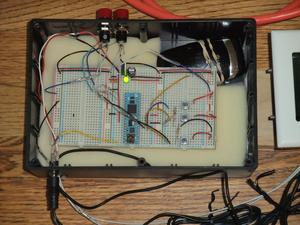

Today I finished the proof of concept prototype of the preheat controller, and did several functional tests with it controlling a lamp. It is set up on a solderless breadboard - I’ll solder up the next version on a BPS 1553 breadboard once I have confirmed that this thing really works. The circuit is inside an enclosure, to protect it, and because the photocell needs a fairly dark environment so help it detect when a call is received. Some of the stuff on the solderless breadboard isn’t needed, such as the three momentary push buttons, which where used during the initial tests before I had the cell phone hooked up to the photocell.

Today I finished the proof of concept prototype of the preheat controller, and did several functional tests with it controlling a lamp. It is set up on a solderless breadboard - I’ll solder up the next version on a BPS 1553 breadboard once I have confirmed that this thing really works. The circuit is inside an enclosure, to protect it, and because the photocell needs a fairly dark environment so help it detect when a call is received. Some of the stuff on the solderless breadboard isn’t needed, such as the three momentary push buttons, which where used during the initial tests before I had the cell phone hooked up to the photocell.

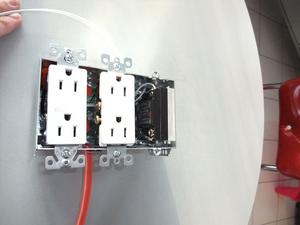

The SSR and all the 120V AC high voltage stuff is inside a standard house electrical box. Two of the outlets are always hot, to provide power for the cell phone charger and the power supply for the Prop. The other two outlets are controlled by the SSR.

The SSR and all the 120V AC high voltage stuff is inside a standard house electrical box. Two of the outlets are always hot, to provide power for the cell phone charger and the power supply for the Prop. The other two outlets are controlled by the SSR.

The CdS photocell is basically a resistor whose resistance changes depending on how much light is shining on it. It is secured to the cell phone display with a rubber band.

The CdS photocell is basically a resistor whose resistance changes depending on how much light is shining on it. It is secured to the cell phone display with a rubber band.

I’m using an NTE RS3-1D25-24T SSR. I was surprised to see that the label says it needs 4V DC to control it, as the spec sheet says it only needs 3V. The Prop is a 3.3V device (however only 2.7V is guaranteed as output), to I was concerned. But, it works.

I’m using an NTE RS3-1D25-24T SSR. I was surprised to see that the label says it needs 4V DC to control it, as the spec sheet says it only needs 3V. The Prop is a 3.3V device (however only 2.7V is guaranteed as output), to I was concerned. But, it works.

The enclosure and electrical box are screwed to a piece of wood to keep them tied together as one assembly.

The enclosure and electrical box are screwed to a piece of wood to keep them tied together as one assembly.

Winter Flying

- Details

- Written by Kevin Horton

- Hits: 2438

The weather has been fairly poor most of the last two weeks. We’ve had snow almost every day, so the flying opportunities have been few and far between. I managed to get out to the airport on Wednesday though. First, I got quite a bit of exercise clearing snow between the hangar and the taxiway. I’m the only guy in the hangar who is flying this winter - one of the other guys has gone south, and Ron, the hangar owner, is in the middle of a big cockpit refurbishment. So, if I don’t clear the snow in front of the hangar, it probably won’t get cleared by anyone else. We had a bit of freezing rain a few days before my hangar visit, and I hadn’t had a chance to clear the snow away first. Thus the freezing rain landed on top of some snow drifts, and this produced quite a ridge on one side of the ramp to the hangar. It was quite a job getting a wide enough path cleared so I could go flying. Lesson learned - get out to the hangar more often to clear snow, as it is much easier when it is fresh.

It had been quite cold overnight, so I preheated the engine for 2.5 hours before attempting a start. I almost didn’t get it started, as it was quite slow to turn over. Lesson learned - I clearly need a longer preheat time when it is cold. Today I finished the first prototype of a remote control preheat system - I’ll install it the next time I’m at the hangar. This should allow me to select the preheat ON several hours before arriving at the airport.

The runway was very, very icy. The official runway condition report was 70% ice, 20% packed snow and 10% bare and dry, and that looked about right. Fortunately the wind was very light, or I wouldn’t have attempted to go flying. The taxiing and take-off were uneventful, but I did get sideways for a short period during the landing roll out. I managed to get the aircraft straightened out before it hit a spot with some traction, so no harm was done, except to my heart. Hopefully we’ll get some warm sunny days sometime soon to clear some of the ice. Otherwise, I’ll have to restrict the flying to days with very low crosswind.

We’ve had a bunch more snow since Wednesday. I had hoped to get out to the airport to clear the snow today, but there was so much fresh snow down that I was pretty sure the taxiway to the hangar would be impassable. I didn’t want to risk getting the car stuck, so I stayed home. They should have the taxiway cleared by tomorrow afternoon, so I’ll probably head out to clear it out.

Vertical 8s

- Details

- Written by Kevin Horton

- Hits: 3275

The first serious cold snap of the season hit earlier this week. The overnight lows were in the -20 deg C (-4 deg F) range for several nights. Saturday my schedule allowed me to spend most of the day at the airport, so I plugged in the preheat at 10:30 AM, then went into Smiths Falls to do some final Christmas shopping. I started the engine just after 2 PM to go flying.

I had planned on measuring glide performance at idle - I wanted to compare the performance at idle to the performance with the engine shutdown. But there was a fair bit of snow on the taxiways, ramp, and on the runway in a few places. I decided I should remove the wheel pants, to avoid the risk of them filling with snow and then freezing to the wheel and brakes. The aircraft has more drag with the wheel pants OFF, which would invalidate any comparisons. So, I switched to Plan B, which was to do some aerobatics.

First, I did a quick cruise performance check at 7500 ft. The speed at 2400 rpm, full throttle, leaned to 50 deg F lean of peak EGT was about 157 kt TAS at a fuel burn of 8.4 US gallons/hr.

Given that it was fairly cold, I decided to try some manoeuvres that probably wouldn’t be possible in the summer. I experimented with loops from very slow speed. I found that I could get the aircraft around loops starting at 100 kt IAS. They were pretty ugly, as the airspeed was very slow going over the top, but they worked.

Next, I decided to try a manoeuvre that I used to enjoy in the Canadair CT-114 Tutor (Canadian military jet trainer) - if you’ve seen the Snowbirds aerobatic team, you’ve seen some Tutors. The Tutor had enough vertical penetration to do what we called a “Vertical 8”. This was a half loop, followed by a roll to upright, then a loop, followed by a roll to upside down, then the second half of a loop. The manoeuvre would look like a figure eight - two balls, one on top of the other. In the Tutor, you started at 350 kt, pulled 5 g on the first half loop, and started the second one at about 200 kt. In the winter, when it was very cold, we could do what we called a “Snow Man”, which was like a Vertical 8, but with a third ball on top. You started at VNE (412 kt), and pulled max allowed g (7.33 g) for the first one, and you were going very slow over the top of the third one, but it would make it around.

In the RV-8, I was quite impressed to find that I could start from 180 kt on the bottom of the first half loop, and have 100 - 110 kt at the start of the second loop. I pulled to idle coming down the back side of the loops, and there was no problem keeping the speed well below VNE (200 kt), as long as I kept the g on.

I really didn’t expect that this aircraft would have what it took to do a Vertical 8.

Slow Week

- Details

- Written by Kevin Horton

- Hits: 2780

I didn’t do any RV flying or maintenance work in the last week. We had two days of quite dreadful weather as a major winter storm went through mid-week. Yesterday the weather was very nice, but I couldn’t get away due to Christmas party duties. We went to a work Christmas party last night, and it had a pot-luck format. Terry shouldn’t be doing any major cooking right now (she isn’t supposed to attempt to look down while those two neck vertebrae fuse). So, I got Shanghaied to do most of the work to make a big batch of Beef Bourguignon, under very close supervision from Terry, who is an excellent cook. It was a lot of work, but the result turned out very well.

I did spend quite a bit of time researching various options to have the aircraft engine nicely preheated when I arrive at the hangar. At the moment, I plug in the Reiff preheat system after arrival, but it takes much longer than I would like to warm things up. Some folks leave the preheater plugged in all winter, but I’ve heard too many stories about this practice causing condensation inside the engine which may lead to significant corrosion. Reiff sells a very nice Beeper Box, which is triggered by a cell phone or pager, but it costs almost $400, and you need to supply your own cell phone or pager. I decided that I could make an equivalent device for much cheaper, plus it would be an interesting project.

I still have ideas about making a pitch axis autopilot using a Parallax Propeller microcontroller (EiED article). I’ve ordered a Propeller CPU to use for this preheat remote controller. The Propeller is overkill for this task, but using it will give me a headstart on learning how it works. I hope to have the remote preheat controller working in a month or so. If it works, I’ll publish a How-To somewhere.

Oil Change

- Details

- Written by Kevin Horton

- Hits: 2913

This time of year you need to take advantage of good days of weather whenever they present themselves. Wednesday morning I did a scheduled check ride in the Cessna Citation II business jet, and it was such a beautiful day that I took some comp time and headed to the hangar for the afternoon.

I did a quick flight to heat up the oil, then changed the oil and filter. I used the Avery Tools oil filter drain kit to drain the oil out of the oil filter before I removed it. It worked slick as you know what. I hardly dropped a drop of oil when I pulled the oil filter off the back of the engine. This tool is a keeper.

I ran out of time, so I didn't get the cowling back on the aircraft on Wednesday, so I attached that Saturday afternoon. I discovered to my great dismay that a rivet had pulled out of the fibreglas on the transition from the upper cowling to the plenum chamber. I made a temporary repair, but I need to come up with a better fix.

After fixing the pulled rivet, I went flying. I had planned to do a long glide performance flight, to gather descent data at idle, to compare to the results with the engine shutdown. But, I was tired after fighting with the cowling repair, and didn't have the energy required to do an hour and a half of accurate flight testing. So, I ditched that plan, and instead I flew down to Brockville for a circuit, then up to Ottawa for two practice instrument approaches. It had been over 15 years since I last flew a localizer back course (BC) approach with a lowly Course Deviation Indicator (CDI), so this was a good training exercise. All the aircraft I have flown IFR in the last 15 years have been fitted with Horizontal Situation Indicators (HSI). With an HSI, on BC approach, the track bar shows lateral deviation in a conventional sense, but with a CDI, the deviations are reversed, which really messes with your head.

Terry is recovering reasonably well from her surgery. She had her sutures removed on Thursday, and the incision is healing very nicely. She had quite a bit of pain on Tuesday and Wednesday, which was discouraging. But, the nurse who removed the sutures on Thursday gave us some excellent recommendations on what she should do differently to avoid the postures that were triggering the pain. Now that we have a better idea on what is triggering the pain, she has been able to avoid it for the most part. We are encouraged.