Radio Still Dead

- Details

- Written by Kevin Horton

- Hits: 3388

I was in Wichita all week, doing some flight testing. I had the wiring odds and ends I needed to rewire the bad intercom connector delivered to the hotel, as that would be quicker than shipping them to Canada. I spent almost a day and a half at the hangar this weekend, rewiring the connector, and then putting everything back in place. But, the COM 1 transmission problem remains. Arrghh!! I’m pretty frustrated right now.

The COM 1/COM 2 selector switch was working, so I did a short test flight which confirmed that while COM 2 is working OK, COM 1 is still a problem. I tried radio checks with Smiths Falls Flying Club, Gatineau Radio, Ottawa Tower, and two aircraft flying in the area. No one answered.

I’m now wondering whether the intermittent bad connection I found was maybe a red herring. Maybe that connector was working, and I’ve got another problem. I'll track down another local aircraft with a GNS 430W, so I can try my GNS 430 in that aircraft to confirm whether it is working or not. I’ll also recheck the wiring to make sure it is OK, and I’ll check the antenna and its coax. The intercom is also a question mark. If need be I’ll wire up a test harness to bypass the intercom.

Radio Snag Found

- Details

- Written by Kevin Horton

- Hits: 3238

Yesterday evening local RV-7A builder Jim M. came by the airport to help me with radio functional checks. He sat by the radio in the Smiths Falls Flying Club and responded to a whole series of radio checks. I confirmed that all transmissions on COM 1 (GNS 430W) were carrier only, from front and rear seat, with two different head sets. COM 2 (MicroAir 760) worked, but I discovered that there is an issue with the COM 1/COM 2 selector toggle switch on the audio panel. This switch seems to be intermittent in the COM 2 position. It works properly, if I push it slightly upwards while transmitting. I’ll need to send the PMA 4000 back to PS Engineering some time to get that fixed.

Now that I had a better idea on what worked and what didn’t work, I could narrow down the list of possible causes. The COM 1 Mic Audio high and low wires between the audio panel and the GNS 430W were the prime candidates.

I took some comp time this afternoon and zipped out to the airport to look for the COM 1 problem. I pulled the GNS 430W out of its tray, and disconnected the wiring harness from the back of the audio panel. Some probing with an ohmmeter showed that the COM 1 Mic Audio Lo connection between audio panel and GNS 430W was bad. Some more probing around suggested an intermittent failure somewhere between the DB-25 connector at the audio panel and a Molex connector that joined the audio panel wiring harness to the GNS 430W harness.

I cut a whole bunch of wire ties and managed to free up enough slack so I had reasonable access to the DB-25 audio panel connector while sitting in the front seat. Unfortunately the connector is the type with the wires soldered to the pins, and my soldering skills are nowhere close to good enough to work with stuff this small. But, each of the 18 wires on the connector has a pretty long pigtail before it disappears into the shielded cables. So, I think the best fix is to convert to a connector with individually removable machined pins crimped onto the wires. I’ll completely replace the three wire cable that contains the intermittent connection and crimp new pins on the ends of all the other wires. I need to acquire some more machined pins and a length of three wire shielded cable. I should be able to get that next week, and I hope to rewire the bad connector the weekend of 12-13 March.

Prop Coarse Pitch Stop, Radio Snag

- Details

- Written by Kevin Horton

- Hits: 3444

I got back home Thursday evening from three weeks of flight testing in Wichita. It was a very busy test program, working long hours, six days a week to hold schedule. But, we got it all done, and now I get a breather at home for a week or so before heading on the road again.

The Ottawa forecast was for good weather on Saturday, and it certainly looked good at home, so I headed to Smiths Falls. I was dismayed to see the cloud get lower the closer I got to the airport, and it looked to be very marginal VFR by the time I got there. I have up any thought of heading to Maurice Prudhomme's Fly-In on the Ottawa River. I didn't make it, but RV-9A builder Alfio did, and his photos show the weather was much nicer there.

I removed the spinner and adjusted the coarse pitch stop on the prop while I was waiting for the cloud to lift. I've known for quite a while that the coarse pitch stop was set much coarser than needed. This is an aerobatic prop, which means it goes to the coarse pitch stop if the governor stops sending oil pressure to the prop dome. This ensures the rpm does not increase if oil pressure is momentarily lost while doing aerobatics, but it also means a prop governor failure will cause the prop to go to maximum pitch. I did some testing a while ago, and determined that the pitch would go so coarse that the engine would be drug down to about 1700 rpm, which greatly reduced the power available. The rpm would fall even further as the airspeed decreased, and it looked questionable whether the aircraft could maintain level flight.

I thought I would need to have a prop shop adjust the coarse pitch stop, but I learned a few days ago that this was actually adjustable with the prop installed on the aircraft. There is a threaded rod with two jam nuts extending from the front of the prop dome. Of course it was bigger than any wrench I had, so I zipped into town and bought a new tool. I loosened the jam nut, rotated the main nut three turns CW, then tightened and safety wired the jam nut.

The cloud was breaking up by the time I finished lunch, so I went for a short test flight (brake release to 8000 ft in 4 minutes and 12 seconds - not bad). I discovered that the rpm with full throttle and prop control full aft was now about 2025, and I could maintain level flight, but I wouldn't want to subject the engine to full throttle at that low an rpm for a long period. There was still quite a bit of rpm control in hand at VNE, with an rpm of 2475 with prop control full aft at VNE, so I decided to move coarse pitch stop a bit more and try again. I adjusted the coarse pitch stop another 1.5 turns after landing.

Ottawa Terminal didn't respond to any of my radio calls during this flight, and another local pilot told me after landing that my radio transmissions were carrier only, with no audio modulation. Drat. I know it was working fine earlier in the month, so this is a very recent problem.

I did some quick radio/intercom/headset troubleshooting, but found no obvious cause of the issue. Unfortunately all my avionics manuals and wiring diagrams were at home, so I couldn't really dig too deep into things. After studying the docs later I have come up with a long list of things to check, but the first order of business is to properly identify the problem. I'll get someone to man the Flying Club radio as I try front seat transmissions on Com 1, Com 2 and also Emergency Mode on the Intercom (which supposedly bypasses the intercom, tying the front seat headset directly to Com 1). Then I'll try rear seat transmissions on Com 1 and Com 2, then change headsets and repeat it all again. The results of that matrix should help me narrow down the list of things to check next. Hopefully I can easily find and fix the problem, as I won't be able to do much flying until I sort this out.

Cruise Performance With Wheel Pants OFF vs ON

- Details

- Written by Kevin Horton

- Hits: 6100

I've been down in Wichita for the last week, doing testing of the Global Vision Flight Deck (Bombardier site) (images) avionics update to the Bombardier Global Express. We've been working long hours, six days a week, but finally took today off to let everyone catch their breath. I did laundry and relaxed. This afternoon I finally found some time to take another look at the wheel pants OFF cruise performance data.

I've been flying with wheel pants OFF for several weeks, as there is frequently some snow on the taxiways and ramp. I don't want to risk having snow collect in the wheel pants, which may lead to frozen brakes, as the warm brakes can melt some of the snow, which will then freeze in flight. I was interested to see how the cruise performance compared to what it is with wheel pants ON, so I gathered some cruise data on flights 103, 104 and 107. I also had some data from last winter, on flight 51, before the aircraft was painted.

I analyzed all the data last weekend, and since then I have been puzzling over the fact that the data from flights 51 and 107 sits about 3 kt slower than the data from flights 103 and 104. I finally realized a few days ago that the flight 51 data was from before the aircraft was painted, and it was fairly dirty then, as I had never washed it. I have done a pretty good job keeping it clean of grit and bugs since it was painted. So, the three knot speed difference on that flight may represent the effect of dirt and bugs.

One other possibility was that I now had a small static system leak, which would make the airspeed read a bit too high. I did a static system leak check after installing the autopilot, and there were no leaks at that time, but perhaps a new leak had developed. To close off that issue, I did a static system leak check before flight 107, and it was completely leak-free.

Or, perhaps the engine power has increased as it has broken in. This is a possible explanation, but the power would have to increase by 6% to explain the observed speed increase. I really doubt it has increased this much between 50 and 100 hours time on the engine - I would expect the big changes in power to occur in the first ten hours.

I checked back to look at data with wheel pants ON, before and after paint. I don't have a lot of cruise performance data with wheel pants, before paint, and the available data isn't the best quality. But it shows speeds about five knots slower than after paint.

I note that the CAFE Foundation did a before and after test to check the speed increase due to waxing their Mooney. They found a 2.8 mph speed increase from a wax job, so it is quite plausible that the speed of my aircraft increased 3 kt from a paint job.

The fact that three of the four data points on flight 107 sit several knots below the line from flights 103 and 104 is puzzling. The engine was running a bit rough during the lowest power point on flight 107, with the EGT on #4 cylinder gradually climbing during the test point. I think one of the plugs on that cylinder was perhaps not firing properly, and that would have reduced the power, which could explain why that point is off the line. But the two middle points on that flight have no obvious reason why they shouldn't match the others. The engine was running smoothly, and the data shows nothing obviously wrong. I'll clean the spark plugs, and then do some more testing in that range of conditions.

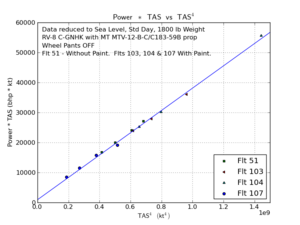

Here is the data for wheel pants OFF, all corrected to sea level, standard temperature, 1800 lb weight. Conventional theory says that a plot of Power * TAS vs TAS^4 should make a straight line. You can see that the four points on flight 51, without paint, and three of the four points from flight 107 sit a bit to the left of the line through the rest of the points.

Here is the data for wheel pants OFF, all corrected to sea level, standard temperature, 1800 lb weight. Conventional theory says that a plot of Power * TAS vs TAS^4 should make a straight line. You can see that the four points on flight 51, without paint, and three of the four points from flight 107 sit a bit to the left of the line through the rest of the points.

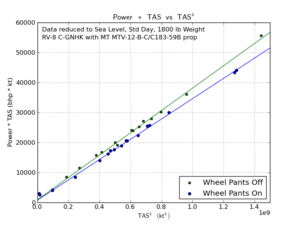

Here we see Power * TAS vs TAS^4, at sea level, standard day conditions from both wheel pants OFF and wheel pants ON.

Here we see Power * TAS vs TAS^4, at sea level, standard day conditions from both wheel pants OFF and wheel pants ON.

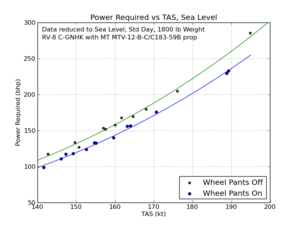

Here we see Power vs TAS, at sea level, standard day conditions with both wheel pants OFF and wheel pants ON.

Here we see Power vs TAS, at sea level, standard day conditions with both wheel pants OFF and wheel pants ON.

Note that the actual testing was not done at sea level, standard day, 1800 lb weight. The data analysis technique corrects each test point to standard conditions, keeping the same angle of attack. Some of the testing was done at fairly light weight, which leads to a low angle of attack. When the points are corrected to 1800 lb, this implies that the speed would be higher to achieve the same angle of attack. It would take a large amount of power to fly at this high speed at 1800 lb at sea level, which is why you see the one point at 280 hp and 195 kt. This does not imply that my aircraft is anywhere close to being capable of achieving that speed, as it only has 200 hp. This analysis simply says that the aircraft could achieve 195 kt without wheel pants, if it had 280 hp.

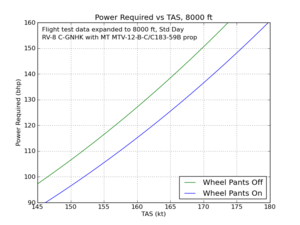

And finally, here we see Power vs TAS, at 8000 ft, standard day conditions with both wheel pants OFF and wheel pants ON.

And finally, here we see Power vs TAS, at 8000 ft, standard day conditions with both wheel pants OFF and wheel pants ON.

Unusable Fuel Check - Right Tank

- Details

- Written by Kevin Horton

- Hits: 3136

I went out to the airport this morning to be part of a work party that was clearing snow from around the runway and ramp lights. It took about two hours to get the job done, then I cleared the snow in front of the hangar.

After lunch I did a static system leak check, to confirm no impact on airspeed system accuracy. I have noted that the recorded airspeeds are about 3 kt higher than they were before the aircraft was painted. This may be due to less drag from the clean, smooth paint job. Or, it could have been an artifact of a static system leak, which would cause the airspeed to read too high.

Then I drained most of the fuel from right fuel tank, and poured it into the left tank, so I could check the unusable fuel quantity in the right tank. I selected the left tank for take-off and climb to 2500 ft, then selected right tank as I circled overhead the airfield. I selected the left tank after the engine faltered, then returned for landing.

After landing, I drained less than 0.1 lb of fuel from the right tank, so the unusable fuel is less than 0.02 USG. 21.68 USG were required to fill the tank, so the usable fuel is more than 21.6 USG. The left tank had 21.47 USG usable fuel, so I will claim 43 USG usable fuel for the whole aircraft (Van's spec is 42 USG, but that seems to be conservative).

After filling both tanks, I took off again, intending to do some more cruise performance testing with the wheel pants off. But, I discovered the weather wasn't nearly as nice as I expected, with a snow shower moving in. I aborted the flight and landed after 20 minutes.

ACK 406 MHz ELT Approved

- Details

- Written by Kevin Horton

- Hits: 3497

ACK Technologies finally got their 406 MHz ELT approved. They've been working on the approval for well over a year, and every time it looked like they were getting close there would be some issue with the interpretation of the test results that required another retest.

I've ordered one to replace my ACK 121.5 MHz ELT - it should ship as soon as Aircraft Spruce gets them in stock. I've already run the wire under the floor to feed GPS position to the ELT, so it hopefully shouldn't be too big a job to install it.