C-GOGO - My Work is Done

- Details

- Written by Kevin Horton

- Hits: 2454

I had the day off today, and the weather was perfect. Aerosport Power couriered Chris a new starter overnight Monday night, and he got it installed Tuesday evening. This morning I did a 2.2 hour flight, which means the aircraft now has over 5 hours of flight time, and Chris can legally fly it.

Cowling Repair

- Details

- Written by Kevin Horton

- Hits: 3108

I did several fibreglass work sessions this week, first to repair the damaged cowling, and then to modify the transition piece so there would be clearance to the baffles.

Here we see the problematic transition piece, as removed from the aircraft.

Here we see the problematic transition piece, as removed from the aircraft.

I cut off the corner that hits the baffles.

I cut off the corner that hits the baffles.

I used modelling clay as a mold.

I used modelling clay as a mold.

Several layers of fibreglass were used for the replacement corner.

Several layers of fibreglass were used for the replacement corner.

Here is the piece before adding filler to smooth the new part. The modified piece is about an inch narrow than the original part.

Here is the piece before adding filler to smooth the new part. The modified piece is about an inch narrow than the original part.

I hope to get to the hangar some evening this week to put it all back together.

C-GOGO - Two More Flights

- Details

- Written by Kevin Horton

- Hits: 2732

I’ve got a huge amount of banked time off at work, and the weather looked good on Friday, so I got another flight off on C-GOGO late Friday morning. The winds were directly across the runway, blowing about 10 kt when I took off, but they were a bit higher when I landed. It was just a 20 minute flight, as we wanted to confirm that the big oil leak from the first flight had been fixed. We pulled the cowling, and found just a tiny bit of oil - it wasn’t clear whether there was still a very small leak, or whether it was residual oil from the previous big leak. But it certainly wan’t anything of great concern.

Unfortunately, the winds seemed to increase a bit more - the report from Ottawa was 25 kt, and 18 kt at Gatineau, the two closest airports that have weather reports. I didn’t want to risk too much crosswind on an aircraft that I was still feeling out, so we cancelled the planned second flight of the day.

Saturday was just about perfect, so I did a 2.2 hour flight in the morning, with some engine break-in and a few stalls up at altitude. 2.9 hours on the aircraft, and 2.1 more to go to make 5 hours so Chris can fly it. We pulled the cowling again, and still saw a tiny amount of oil. Looks like a small leak somewhere.

After lunch, Chris was going to taxi the aircraft to the fuel pumps, to fill it up for my next (and likely last) flight. Chris had a Super Decathlon flight scheduled for the next morning, and would hopefully do his first flight in his RV-8 that afternoon.

But, it wouldn’t crank. The starter solenoid would click, but the engine didn’t turn over. We pulled the cowling, removed the starter cable from the started and hooked up a voltmeter, which showed good voltage at the starter. On a whim, Chris turned the starter a bit by hand, then tried cranking - it cranked. Hmm. Dead spot on the armature? We put the cowling back on, and he tried to start, but once again it refused to crank. Looks like a bad starter. I gave up and went home, while Chris removed the starter. We’ll try again whenever he gets this issue sorted out. Patience.

First Flight - C-GOGO

- Details

- Written by Kevin Horton

- Hits: 2533

Local RV-8 builder Chris H. asked me some time ago if I would do the first few flights on his aircraft. He has hundreds of hours of time in gliders, but much less time in powered aircraft. He ran afoul of a requirement that the first five hours of time in an amateur-built aircraft in Canada be flown by a pilot with at least 100 hours pilot in command time in powered aircraft. He could have flown a rental aircraft for a few hours to crack the 100 mark, but he decided it would be quicker and cheaper to have someone else fly the first five hours.

We tried to get the first flight off Saturday morning, but it was not our day. First, the EFIS/Engine Monitor refused to boot. I could have flown without the EFIS, as the aircraft also has round dial airspeed indicator and altimeters. But, the engine monitor portion of the EFIS had the only engine instruments, so I couldn’t go without it. The failure message indicated the problem was an inability to read the internal flash memory, which contained the operating system. The EFIS can also be booted off an SD card, so Chris zipped home to load the needed files on an SD card. That solved the EFIS problem, so we pushed the aircraft outside.

The next problem was that the engine was not sufficiently preheated and/or the battery voltage was too low. The starter barely turned the engine over, and it refused to fire. I climbed out while Chris and RV-8 builder Mark tried using a car to boost the aircraft. It turned over much quicker with a full 14v available, and Chris warmed up the engine. He shut it down, I climbed in and fired the engine back up. Then I discovered that the radio would not transmit. It had been working earlier in the morning, but not any more. After shutdown Chris found the Push to Talk wire broken off at a connector at the bottom of the pilot’s stick. That wiring was hanging loose, and one us us (probably me) must have hit it with his heel while climbing into or out of the aircraft. Three strikes and you are out, so we aborted for the day.

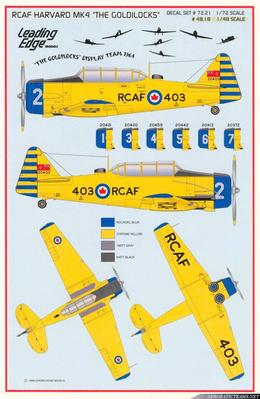

Here we see Chris warming up the engine and charging the battery after boosting from his car to get the engine started. The aircraft is painted in the colours of the RCAF “Goldilocks” aerobatic team. They flew North American T-6 Harvards, and the name was a poke at the RCAF Golden Hawks aerobatic team (team paintings).

Here we see Chris warming up the engine and charging the battery after boosting from his car to get the engine started. The aircraft is painted in the colours of the RCAF “Goldilocks” aerobatic team. They flew North American T-6 Harvards, and the name was a poke at the RCAF Golden Hawks aerobatic team (team paintings).

The Goldilocks signature manoeuvre was a crazy formation, with aircraft flown in large sideslips.

The Goldilocks signature manoeuvre was a crazy formation, with aircraft flown in large sideslips.

We tried again this afternoon, and this time everything went smoothly. I did a 20 minute first flight, with most of that time circling directly overhead the Carp airport. I did a simulated approach, flare and go-around at altitude, then came down for landing, keeping within gliding range of the field the whole time. The aircraft flies nicely.

After flight, Chris and Mark pulled the cowling for a post-flight inspection, and found that there had been a very large oil leak. We abandoned the plans for a second flight on the same day, as Chris must find and fix that leak. Chris later reported that he thinks the problem was a not tight enough connector on the prop governor oil line.

I had planned to do about 2 hours on the second flight, but I’ll shorten that to another 20 minute flight, as we need to make sure the oil leak is fixed before doing any longer flights.

Cowling Troubles

- Details

- Written by Kevin Horton

- Hits: 3470

A little voice in my head insisted that I should pull the cowling off to have a look. It wouldn’t go away, so I gave in and removed the cowling late Wednesday afternoon. I’m very glad I did. I discovered that the aft outboard edge of the air inlet on the left side of the upper cowling was cracked, and almost broken off.

I’ve got an enclosed plenum chamber on top of the engine, and to minimize the air leakage between the cowling and the plenum I fabricated fiberglass and rubber transition pieces. Things are not symmetrical between left and right sides up front, as the engine itself is not symmetrical (the cylinders on the right side are ahead of the ones on the left) and the engine is mounted so the thrust line is offset to one side to help counteract the effect of the prop wash. The transition piece on the right side turned out very nicely, but the one on the left proved more troublesome. It ended up with a bit of overlap where the aft edge of the transition piece overhung the outer edge of the baffle side piece. This raised the possibility of interference when the engine rocked on the mounts during start and shutdown. I watched this area closely over the first few flights, and concluded that there were no signs of any such issue.

A few weeks ago I noted that the outboard rivet that secured the metal mounting flange where the transition piece attached to the cowling had pulled out. I diagnosed the cause as a combination of the engine heat softening the fibreglass and air loads. I replaced the rivet with a #8 screw and nut, using a Tinnerman washer under the screw head to spread the loads, expecting that this would be much stronger than the original rivet.

Well, it turns out that I misdiagnosed the cause of the earlier failure, and my repair was strong enough to transfer the loads to the next weakest point, with was the aft edge of the inlet on the cowling, which almost broke off.

Well, it turns out that I misdiagnosed the cause of the earlier failure, and my repair was strong enough to transfer the loads to the next weakest point, with was the aft edge of the inlet on the cowling, which almost broke off.

Looking closely at the lower edges of the rubber on the transition, I can clearly see marks from multiple pinches where the rubber was jammed between the lower edge of the transition piece and the upper edge of the baffle side piece. So, work to do - repair the cowling and modify the transition piece so there is good clearance to the baffle side.

I repaired the cracked cowling on Saturday afternoon, and plan to modify the transition piece during evenings this week. I’ll cut off the outboard portion and graft on a new part to make it narrower so it no longer overhangs the baffle side, allowing much more room for engine movement during startup and shutdown.

Busy Two Weeks

- Details

- Written by Kevin Horton

- Hits: 2453

It’s been a busy few weeks. I finished my annual King Air C90A recurrent ground school and simulators on Friday, 14 Oct 2011. The very next day, Saturday, I flew to Wichita, and started avionics testing of the latest software version for the Global Vision Flight Deck variant of the Bombardier Global Express on Sunday. It was a productive, very busy week, and I got home on Friday evening.

The weather yesterday was not that great, with lowish clouds, but this morning was a bit better, so I took advantage to do a local flight. I zipped over to Ottawa to do some practice instrument approaches. I’m still experimenting to find the best way to make use of the autopilot during instrument approaches. I did two localizer back course approaches - one was hand flown, and on the other one I used the autopilot. The autopilot cannot couple up to a back course approach, but it can fly a selected track angle using GPS data. It is quite easy to change the desired track angle by one or two degrees to correct for small left or right deviations in the back course. The Trio Autopilot allows the lateral and vertical servos to be used individually, so I manually flew the pitch axis to control the descent while the autopilot handled the lateral servo.

As I was leaving Ottawa on my way back to Smiths Falls, the Ottawa Tower controller commented on how fast the aircraft was (I had the power up, and was doing a bit over 180 kt TAS), and asked how much horsepower the aircraft had.