A few weeks ago I saw a posting on the Van's Air Force forum about the correct hardware to use to attach grounds to the airframe. The RV airframe is made from aluminum. The ring terminals on grounding straps are typically tin plated copper. When you put dissimilar metals in contact, there is the possibility of galvanic corrosion. If there is electrical current flowing, this increases the chance of corrosion. I had worried about the possibility of corrosion where the various components were grounded to the airframe, but I simply assumed that there was nothing that could be done to prevent it.

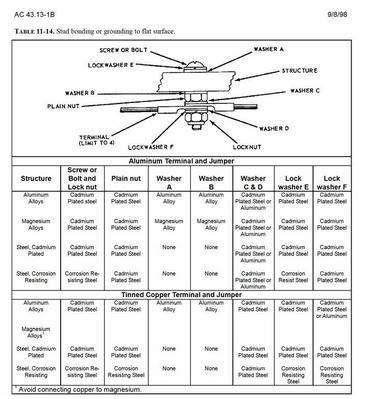

Another builder posted a question about possible corrosion at grounding points, and George McQueen, provided a very useful pointer to the material on this subject in FAA Advisory Circular AC 43-13-1B, Acceptable Methods, Techniques, and Practices - Aircraft Inspection and Repair. I have a copy of this huge bible, a great reference for best practices, but I had missed the section on electrical grounds. AC 43.13-1B suggests to put an aluminum washer between the tinned copper ring terminal and the aluminum airframe. The washer and the airframe are made from the same material, so there won't be any galvanic corrosion at that interface. The corrosion, if any, will occur between the aluminum washer and the tinned copper ring terminal. But the washer is replaceable, so corrosion there is fixable.

Another builder posted a question about possible corrosion at grounding points, and George McQueen, provided a very useful pointer to the material on this subject in FAA Advisory Circular AC 43-13-1B, Acceptable Methods, Techniques, and Practices - Aircraft Inspection and Repair. I have a copy of this huge bible, a great reference for best practices, but I had missed the section on electrical grounds. AC 43.13-1B suggests to put an aluminum washer between the tinned copper ring terminal and the aluminum airframe. The washer and the airframe are made from the same material, so there won't be any galvanic corrosion at that interface. The corrosion, if any, will occur between the aluminum washer and the tinned copper ring terminal. But the washer is replaceable, so corrosion there is fixable.

I ordered some aluminum washers, and they arrived earlier this week. I corrected the ground connections to the airframe.