I've been beavering away a few hours each day on the project. Monday I collated all the snag lists I've created since the start of the project. Any time I found a problem that I couldn't fix right away, or if I stopped a job part way through, I would record it on a snag list, so I would be sure to fix it later. This list covered many pages, with most of the items marked off as already completed. I decided to go through all the pages of the list, and transcribe them into an Excel spreadsheet that I could load onto my Palm PDA. It turned out that there were 75 open items on the list. I started attacking them, and got a bunch done, plus found a few new items to add to the list. I've made net progress of 10 items on the list.

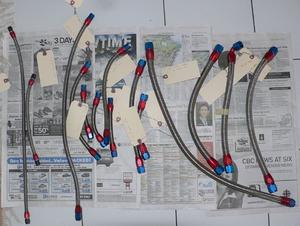

Tuesday morning I removed all the flexible hoses that I had made up, so I could get them pressure tested. It took quite a while to get them all off, as some of them are difficult to get to. One of the inverted fuel system hoses had filled up with oil that had come back through the oil pump. That made quite a mess when I took it off. I made sure to label each hose as I took it off - otherwise it would have been a real jigsaw puzzle figuring out which one went where.

Tuesday morning I removed all the flexible hoses that I had made up, so I could get them pressure tested. It took quite a while to get them all off, as some of them are difficult to get to. One of the inverted fuel system hoses had filled up with oil that had come back through the oil pump. That made quite a mess when I took it off. I made sure to label each hose as I took it off - otherwise it would have been a real jigsaw puzzle figuring out which one went where.

I dropped the hoses off at Kirouac Fluid Industries Tuesday afternoon, and picked them up yesterday. They all passed the pressure test. It cost me $60 to have all 14 hoses tested, but I figure it was worth the expense to be sure to find any problems now, rather than during the engine runs, or in flight. A leaking fuel hose could cause a fire.

Now I need to put the firesleeve on the hoses, and then reinstall them. The firesleeve needs to be clamped in place on each end. Type-certificated aircraft use nice stainless steel band clamps to do hold the firesleeve in place. Many homebuilt aircraft builders just use a few turns of safety wire, which probably works well enough, but really looks amateur. Someone on one of the e-mail lists was complaining about the cost of the stainless steel band clamps, and the tool needed to install them. Someone else suggested that automotive CV boot clamps were a suitable replacement. I spent several hours on Tuesday driving to various automotive parts places, looking at CV band clamp tools, and pricing out the clamps. I only found one place that had a tool, and it was $35. The clamps were going for $3 each, and I need 28 of them. I went on to Wick's web site, to see how much the expensive aviation ones cost - the clamps are $1.33 each, and the tool you need to install them is $7.20 for the cheap one, and $15.28 for the nice one. Time to put an order in to Wicks.