This week I got some wiring clean up work done, and partially installed the flap root end intersection fairings. The flap intersection fairings rivet to the side of the fuselage. I had fitted the fairings when the wings and flaps were temporarily installed, but I had never riveted them in place.

This week I got some wiring clean up work done, and partially installed the flap root end intersection fairings. The flap intersection fairings rivet to the side of the fuselage. I had fitted the fairings when the wings and flaps were temporarily installed, but I had never riveted them in place.

Dimpling the holes was a two person job, with on person inside holding the female dimple die on a weight, and one person outside the male dimple die on a long shaft, tapping it with a hammer. Most of them could be done with the flat plate weight that I made a long time ago.

Dimpling the holes was a two person job, with on person inside holding the female dimple die on a weight, and one person outside the male dimple die on a long shaft, tapping it with a hammer. Most of them could be done with the flat plate weight that I made a long time ago.

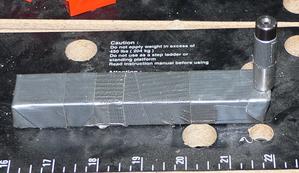

But there were four holes that were too close to a bulkhead, so I drilled a hole near the end of one of my home-made bucking bars.

But there were four holes that were too close to a bulkhead, so I drilled a hole near the end of one of my home-made bucking bars.

But even that wouldn't work for two of the holes. I eventually ended up countersinking a hole in a piece of aluminum plate. The piece of aluminum didn't have enough weight to do the job, but it was easy to hold a hefty bucking bar against the plate.

But even that wouldn't work for two of the holes. I eventually ended up countersinking a hole in a piece of aluminum plate. The piece of aluminum didn't have enough weight to do the job, but it was easy to hold a hefty bucking bar against the plate.

After dimpling, I taped off the perimeter and sprayed some zinc chromate primer for corrosion control on the area to be covered by the fairing.

Yesterday I attacked the dimpling. I could get the rivets near the front myself, with one hand on the rivet gun, and the other hand inside on the bucking bar. Terry tried to help me with the other rivets, but she was having a hard time of it and gave up. I'll Shanghai another local builder to help me finish.

Today, for a change of pace, I installed our new dishwasher. Two trips to Home Depot, plus one trip to a friend's place to get some wood spacers, multiple hours of work, and I am almost done. No leaks, anyway.